3D Scanning Service

How It Works

Step 2

Step 4

Step 5

Step 1: Understanding the Idea and the Object

Our first step is to understand what you would like to achieve with 3D scanning and whether it is the right method for achieving your objective. It’s also important to understand the physical properties of the object itself to know whether it can be 3D scanned and if so, what challenges there are to capturing a usable 3D model. Our specialists will consult with you to understand your requirements and recommend the best approach.

Step 2: Capturing the 3D Scan

3D scanning can be done using different technologies including laser scanning, blue or white light scanning, or photogrammetry. Small to medium sized objects can be scanned under controlled conditions at our facility; larger or immovable objects, or even precious objects can be scanned on location. Our specialists work to capture the most accurate 3D scan possible in order to minimize the post processing steps that follow.

Step 3: Post-Processing the Scan Data

3D scanning produces a digital representation of an object commonly referred to as a mesh. In most cases at the detailed level the surface area of the mesh is imperfect – at high resolution it may have rough edges that need to be smoothed, small gaps that need to be filled, or edges that need to be more accurately defined. To repair these issues with the scan data there is a process of “cleaning” the mesh. The cleaning step may also involve adding reference information to be used in CAD modeling. For some applications the cleaned mesh model is enough, whereas in other applications such as reverse engineering or product development the cleaned mesh model is used as the starting point for CAD modeling.

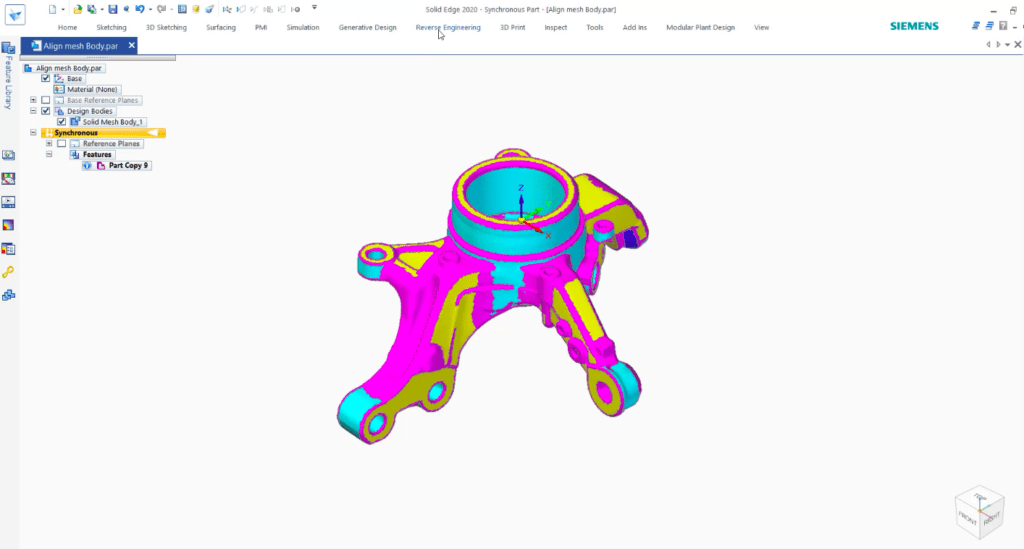

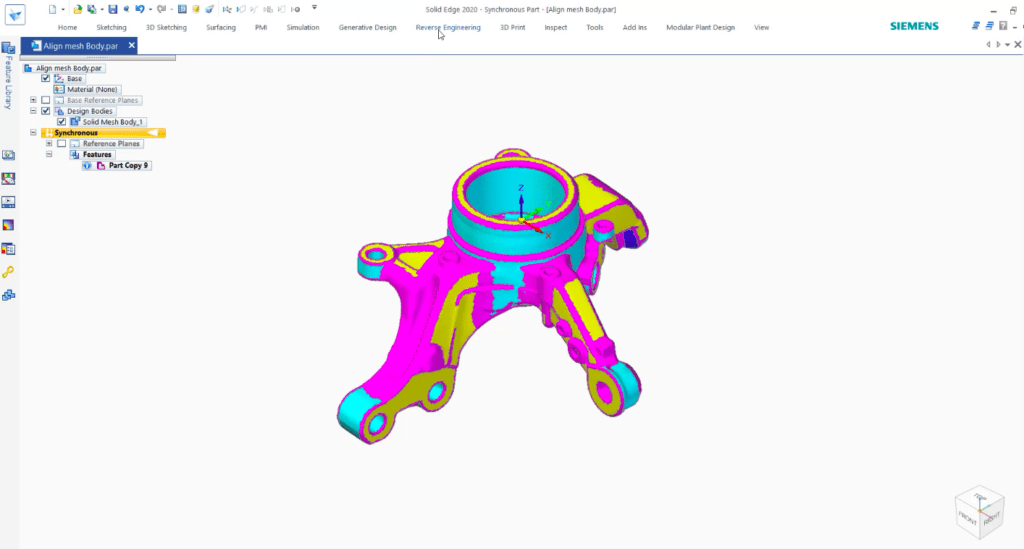

Step 4: CAD Modeling

CAD modeling uses the 3D scan data as the reference model for applying detailed parametric dimensions to the object. Applications that require highly accurate measurements for engineering design and development are done using CAD software. The 3D scanning process is often used to save valuable time in the development of a parametric model.

Step 5: 3D Printing

3D printing can be used with cleaned mesh models or parametric CAD models to create physical prototype of the object. Once the 3D scan model is available it can be used to easily and cost-effectively produce multiple iterations of an object to ensure accuracy and design.

3D Scanning Request

If you would like to learn more, or schedule an appointment for scanning, you can also contact us by email at: 3d@3dherndon.com