CASE STUDY:

Singer Sewing Machine Arm

Creating an Adaptive Arm for an Antique Sewing Machine

DEFINING THE GOAL

3D Herndon had the opportunity to work with an internationally recognized collector of antique sewing machines. The collector needed a rare adaptive arm for a turn of the century, 1890, Singer sewing machine scanned and replicated. This arm could be installed on early model Singers to allow for a hand crank or motor to be attached. This was often a preferred method over the traditional treadle, or foot pedal, locomotion to drive the needle assembly. This bracket was designed with a unique curve to silhouette the form of the Singer as to not obstruct the normal operation of the machine. This was why 3D scanning was chosen to accurately simulate that design.

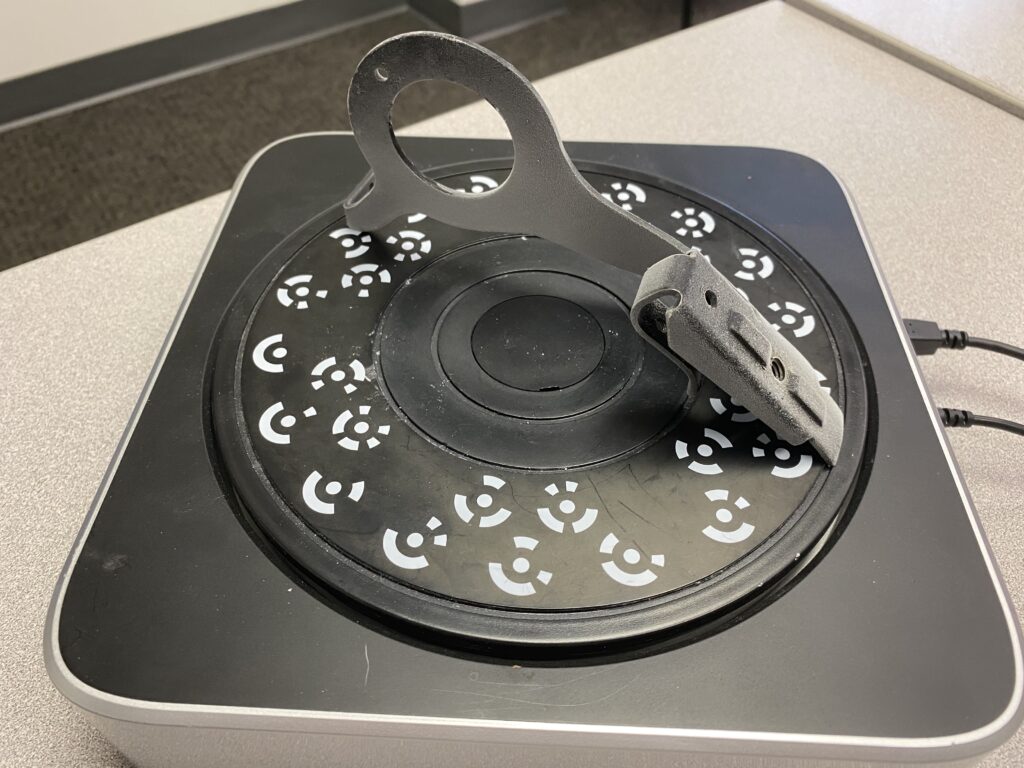

To scan the original brackets, we used the Shining 3D Ein-Scan Pro, a white light high-resolution scanner. Our first challenge was scanning a shiny solid black piece of metal. In white light scanning the cameras on the machine need to be able to see reflected light. Since the brackets were shiny and black, we needed to dull the finish and change the color slightly. A quick dusting of spray dry shampoo solved both issues giving us an easy, non-damaging means to get a great scan.

After the scans were completed, we set to work cleaning and converting the mesh geometry into printable copies of the originals. Using industry leading software, our team created a perfect 3D model of the Singer brackets. Our next decision was to print the parts in a material the collector could verify fitting before eventually printing the parts in its original metal. For this, we chose to use the Sinterit Lisa Pro SLS desktop printer.

This 3D printer allows for complex geometry to be printed easily in sturdy Nylon PA-12, a material used for a wide variety of applications.

The collector brought the antique sewing machine to 3D Herndon to test the fit and was very pleased to see that we had completely accomplished our task of replicating this piece of history.