CASE STUDY:

Custom Phone Stand for Desk Use

Custom Phone Stand for Desk Use

DEFINING THE GOAL

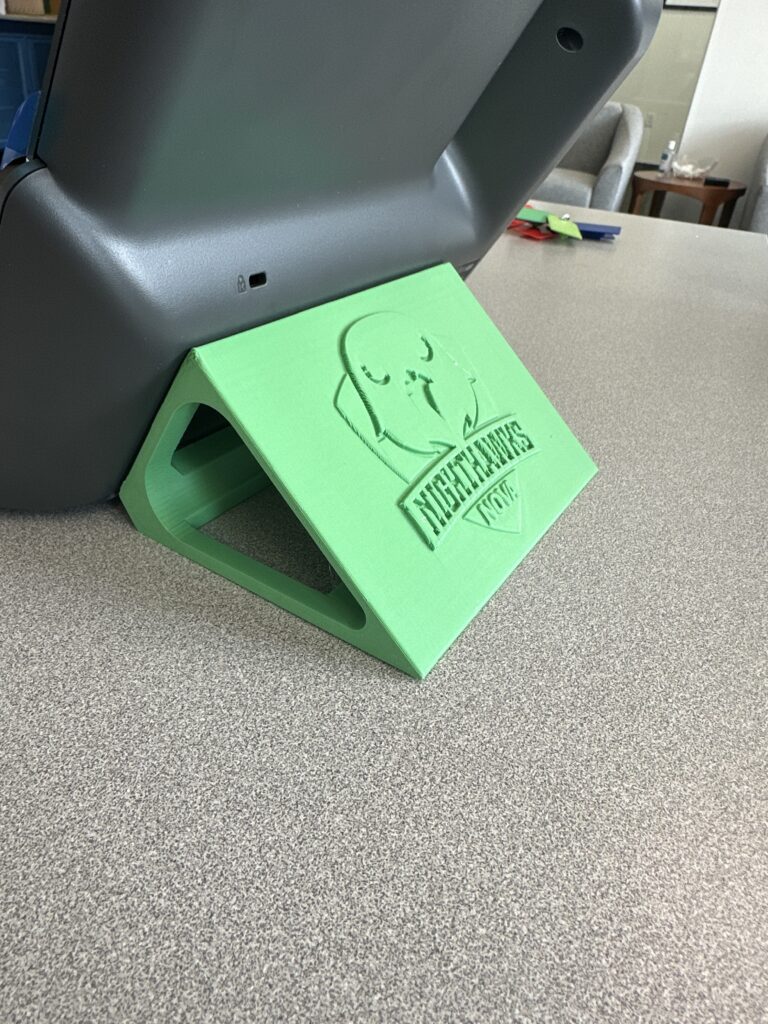

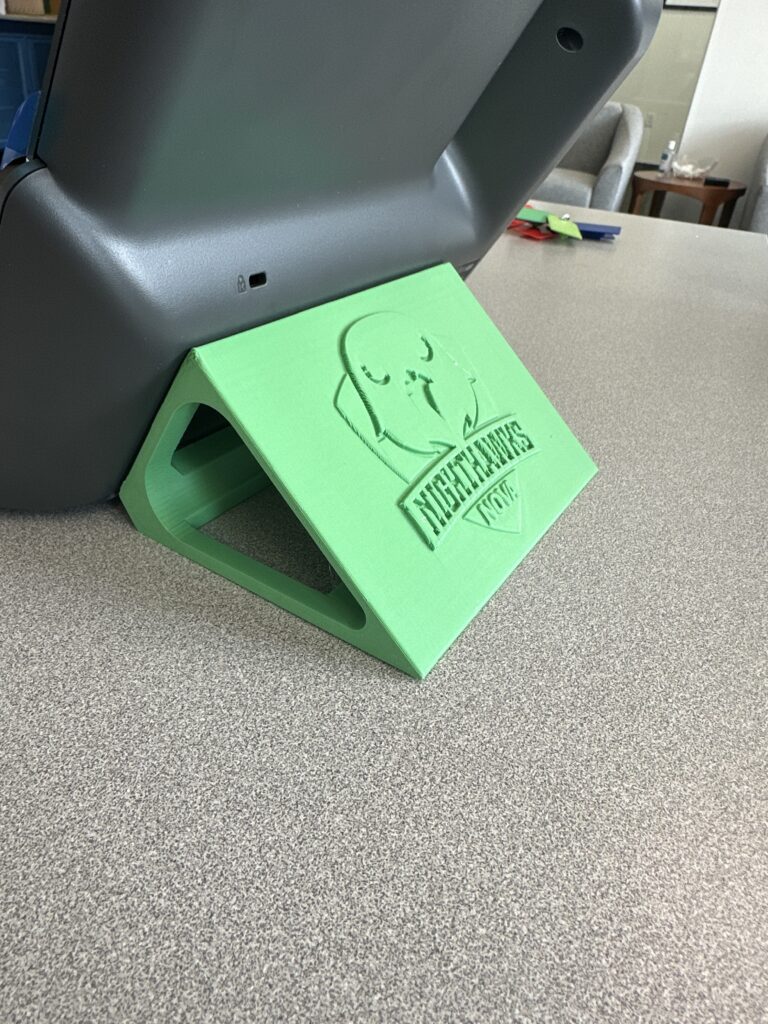

Northern Virginia Community College (NOVA) approached 3D Herndon with a request to re-engineer the wall-mounted phone brackets used in classrooms and offices across multiple campuses to convert them to desktop stands. For better safety and security, the goal was to relocate the phones from walls near entry doors to teacher’s desks where they would be more accessible.

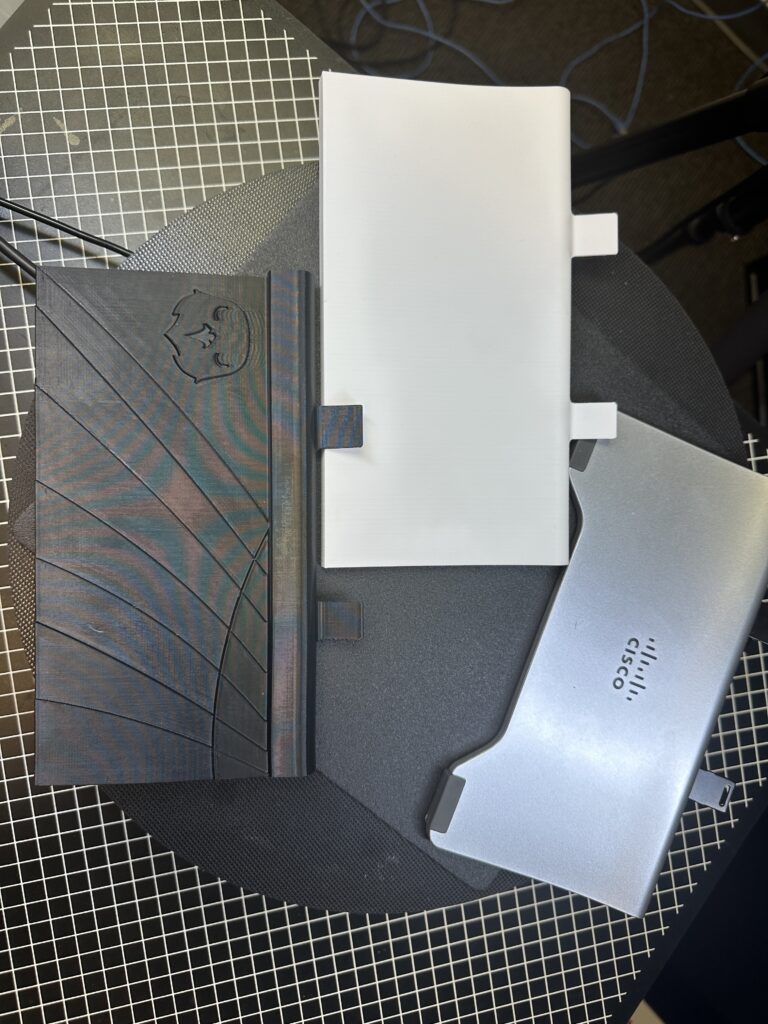

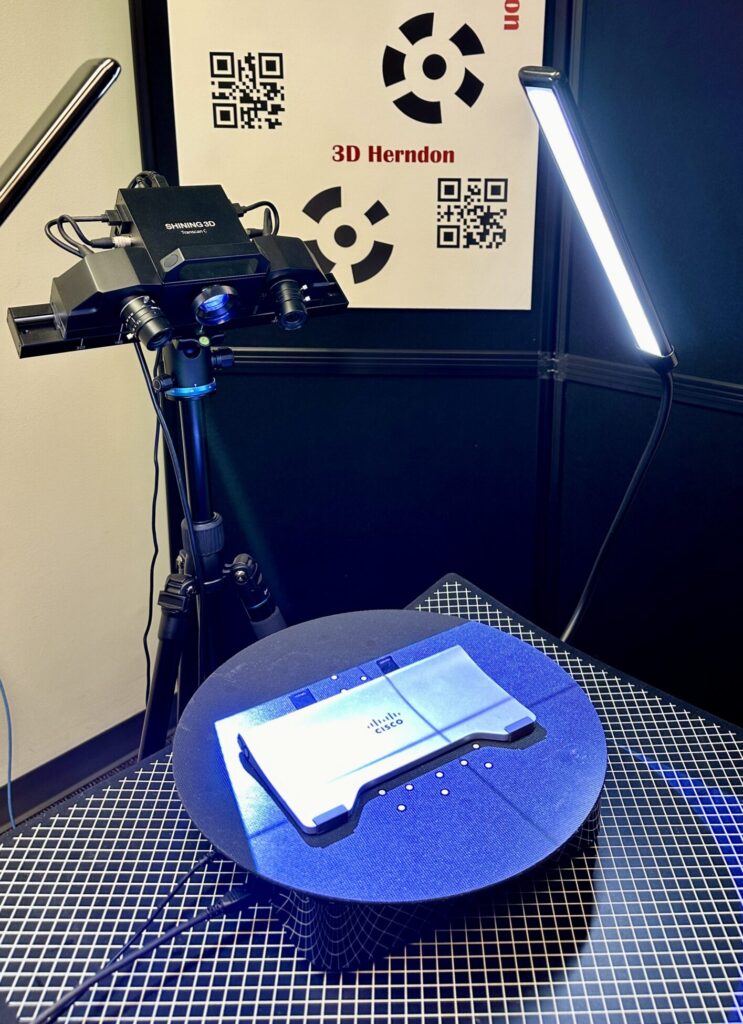

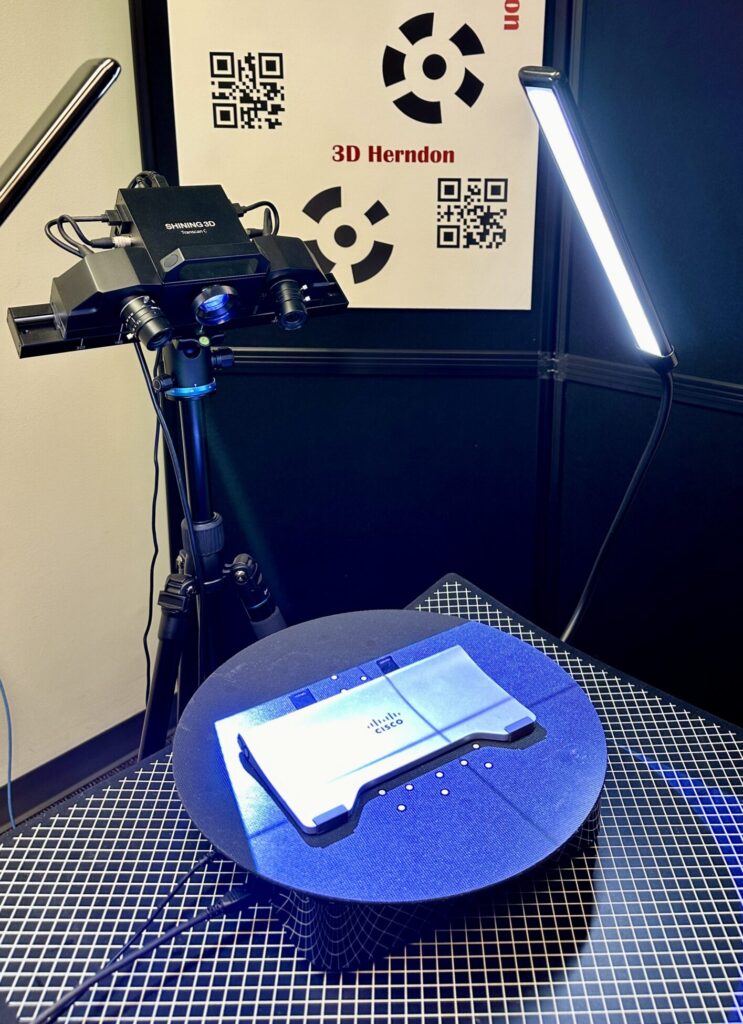

The wall-mount brackets for the phones were no longer manufactured and a desktop version was not available. There was also no digital model available for 3D printing. The challenge was to use an existing wall-mount bracket as the basis for creating a digital version and then adapting that 3D model to a desktop stand.

To create a 3D model of the existing wall-mount bracket, 3D Herndon used an EinScan 3D scanner to capture accurate contours and dimensions. The 3D mesh model generated by scanning was then converted to a CAD model that could be redesigned as a desktop version.

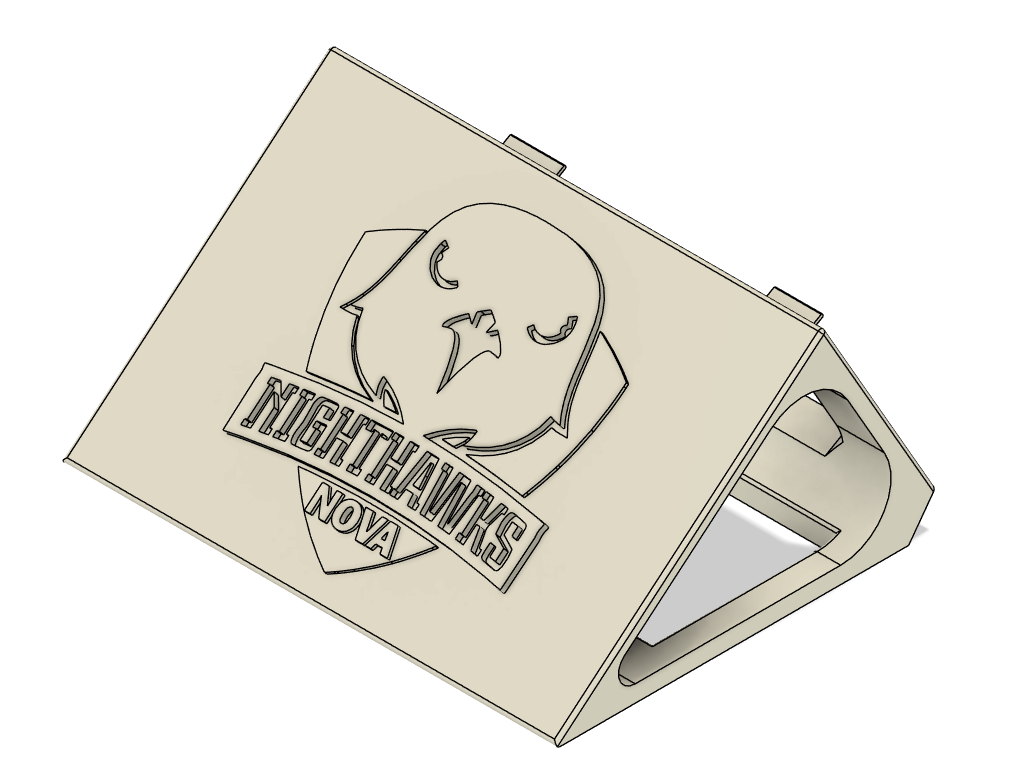

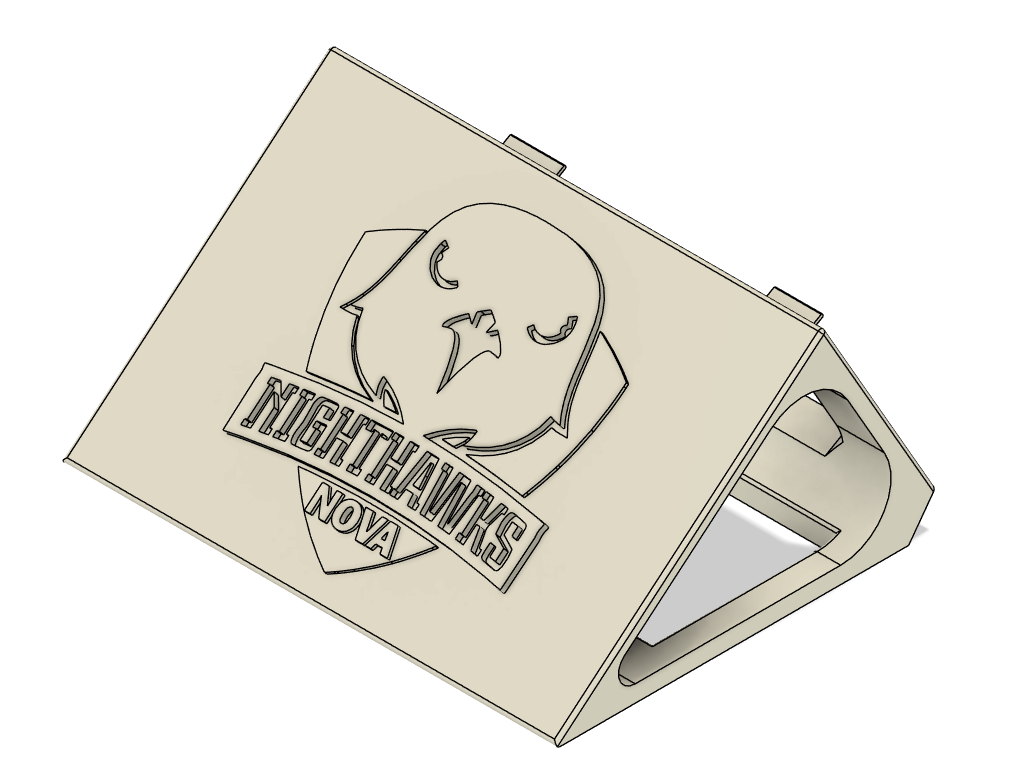

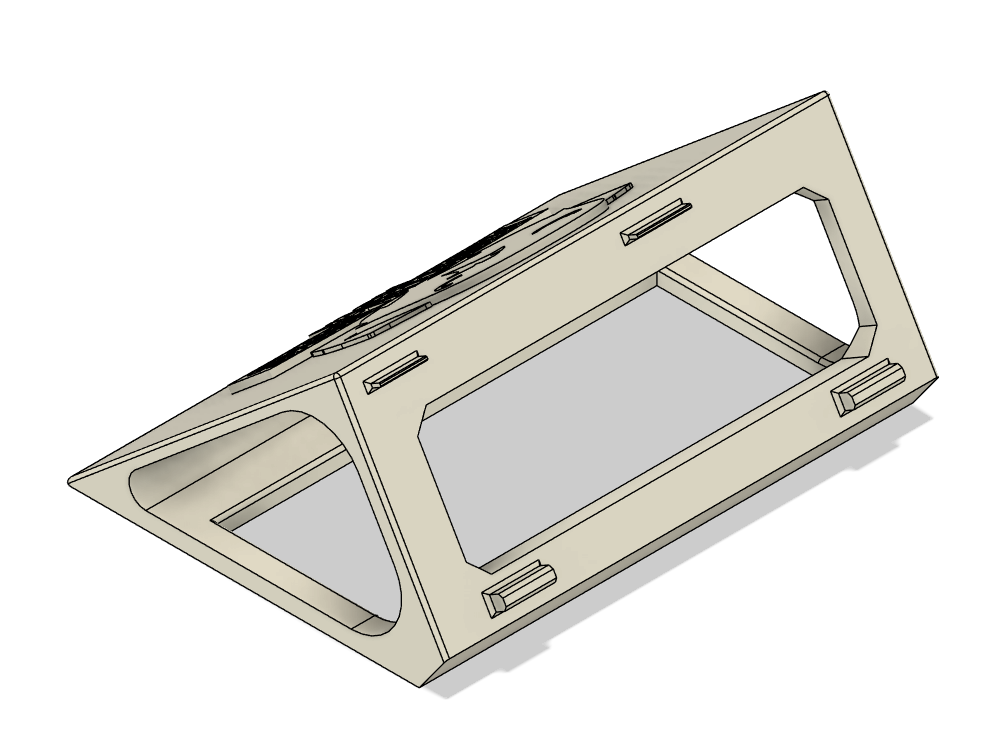

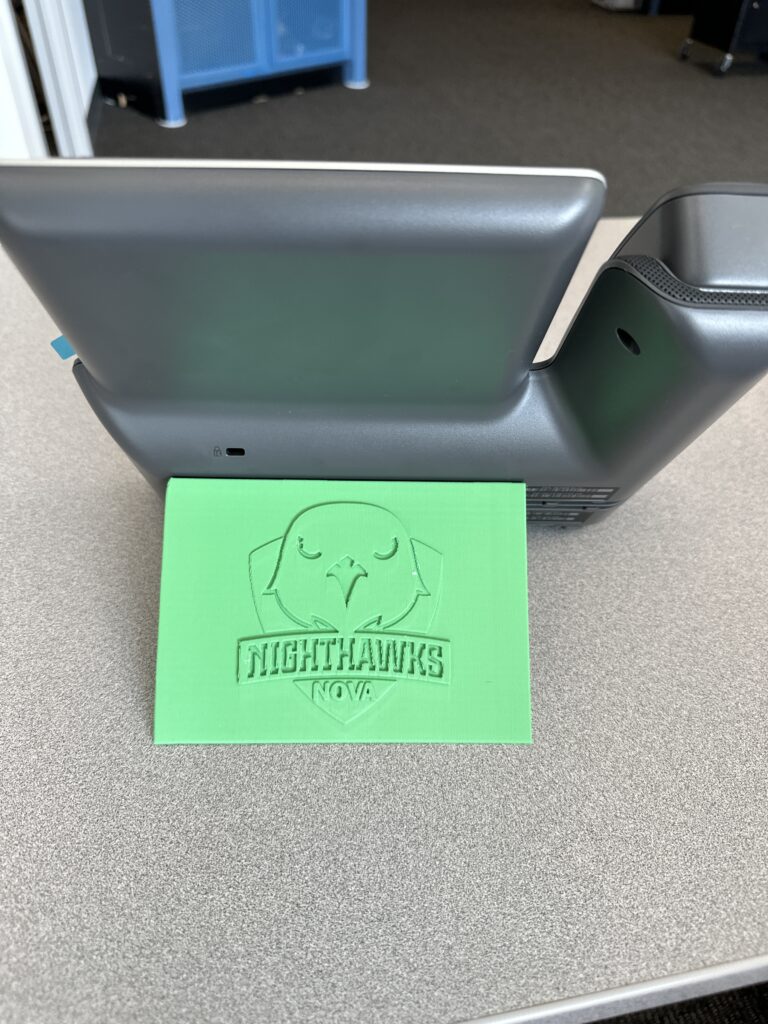

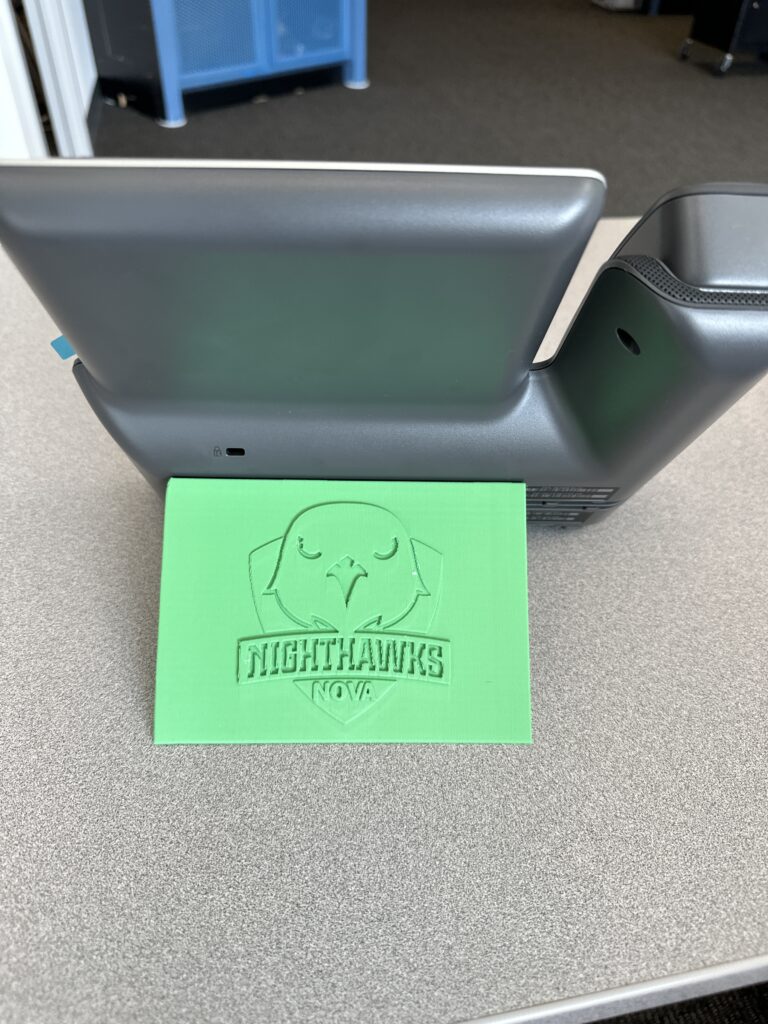

The process of designing the phone stand involved multiple interations of creative design as well as testing engineering functionality. We used CAD software (Fusion360 in this case) to develop a sturdy, stable, functional, and aesthetically pleasing stand. We 3D printed multiple prototypes using an UltiMaker S7 3D printer. Along the way, we added the school’s logo to the customer-facing side of the stand as an attractive design and branding element. Special attention was devoted to ensuring the stand provided stable support for the phone; factors such as weight distribution, balance, and viewing angles were considered to enhance user experience.

The College is excited about the new desktop phone stand design. Not only is the final design an engineering success, but users and visitors are enthusiastic about the incorporation of the school logo as a prominent feature. 3D Herndon produced the first batch of phone stands by 3D printing with the UltiMaker S7. The College is now using the 3D model to produce additional copies of the stand in their own makerspaces across different campuses. They estimate needing as many as 100 units initially with more to come and the possibility to produce them in-house costs about 75% less than buying a standard commercial product.