The U.S. military asked 3D Herndon to develop an advanced capability to create 3D models of urban environments that could be deployed for strategic threat response planning. Public events involving high-profile government officials require an amazing amount of advanced planning and preparation. This includes establishing security perimeters and transport corridors, staging military, law enforcement, medical and other emergency response assets, anticipating a wide range of potential threats and developing action plans. The security services of the U.S. government are continuously developing ways to deploy advanced technologies to assist in this process of strategic threat response planning. 3D Herndon developed a systematic process to produce scalable and detailed modular 3D city maps by combining 3D imaging, digital mapping, 3D design and 3D printing technologies. The first model we produced is the largest and most detailed 3D model of Washington, DC. The solution is designed to support response planning for civilian, military and law enforcement applications.

3D models have certain advantages over both traditional 2D maps and advanced 3D imagery. All three have their place in the process, but flat maps and digital imagery don’t provide the same sense of physical reality that a 3D model does. This can make a critical difference to planners who are trying to envision potential threats, identify potential responses, and train response personnel for events in complex urban environments. Some of the challenges to creating 3D models quickly and accurately include: (a) getting the scale right, (b) getting the topography right, (c) getting the detail of the buildings and infrastructure right (strategic vs non-strategic) and (d) creating a systematic process that can be applied to any environment. Topography is an important factor for understanding mobility, positioning of personnel and equipment, crowd control, and many other factors. The scale of the model is also important – if the scale is too small it will lack the detail necessary, and if it’s too large it becomes unworkable physically. Having enough detail in key features is important for operational planning as well. Knowing where entrances and exits are, how many windows are in a building, how tall certain structures are, what roof lines are like, the dimensions of roads, alleys and pathways, what landscape features come into play can all be critical for tactical planning. And finally, developing an easily repeatable process to generate physical models of different locations requires the integration of all the technology elements.

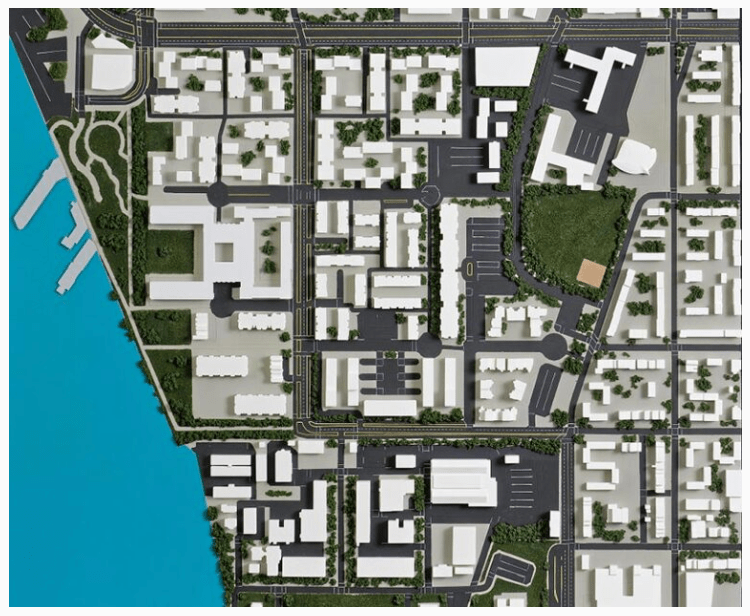

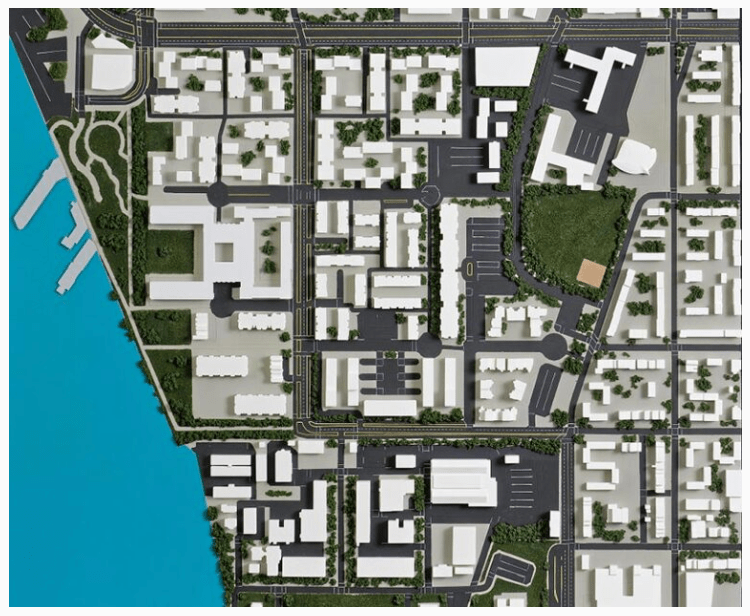

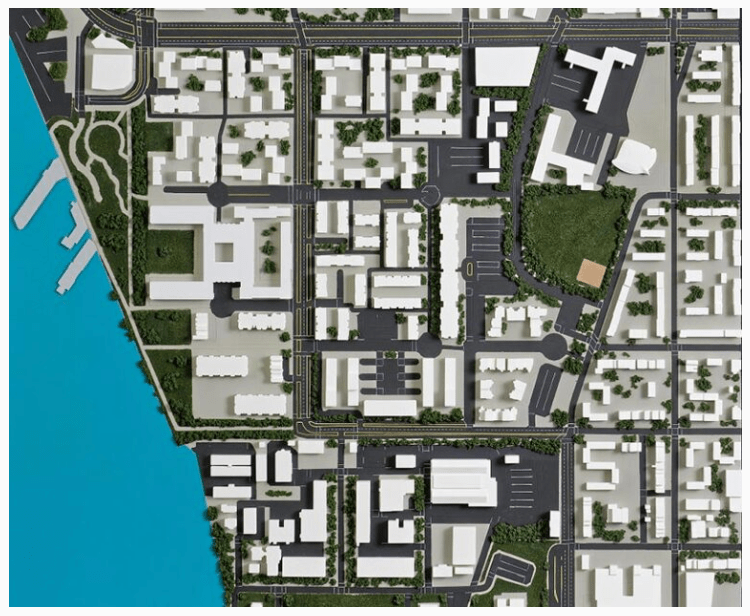

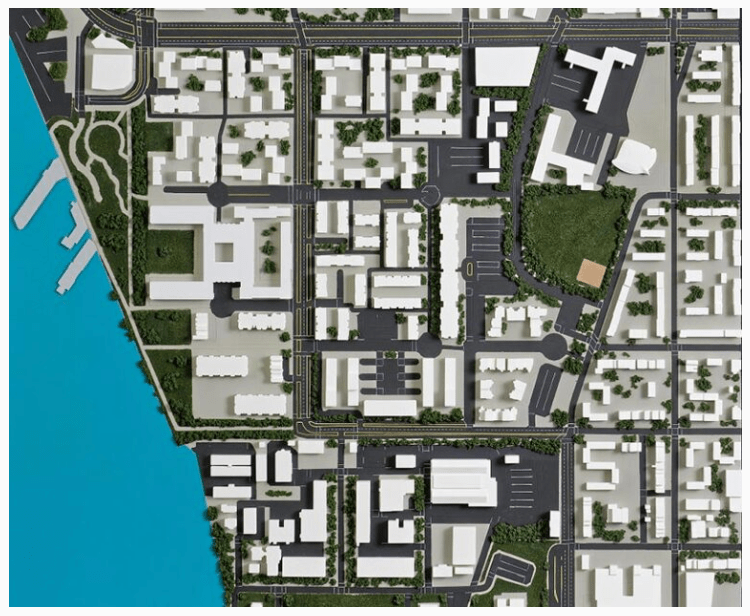

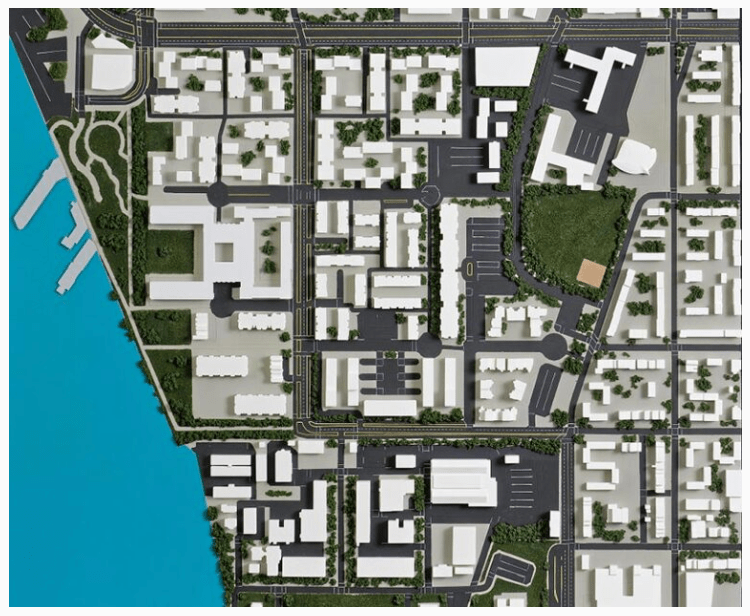

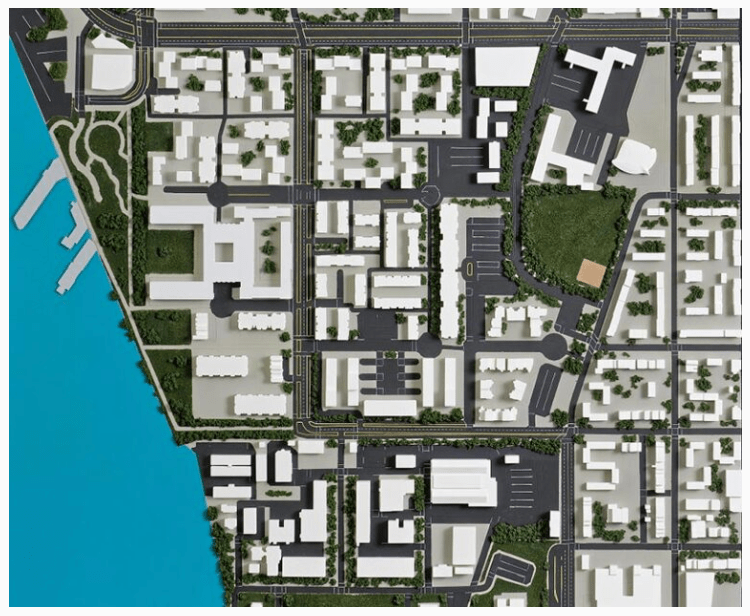

To create the model in digital form we combined different technologies. First, to get an accurate representation of the urban topography we combined lidar imagery and digital satellite maps. Second, to capture a detailed digital representation of the above-ground infrastructure we integrated a variety of different digital imaging solutions. These were used to map the physical layout of roads, buildings and other physical features which were then superimposed onto the digital topographical map. Third, we added the important details to the digital mesh for assets such as the buildings or landmarks that were designated as strategic structures as well as important landscape features.

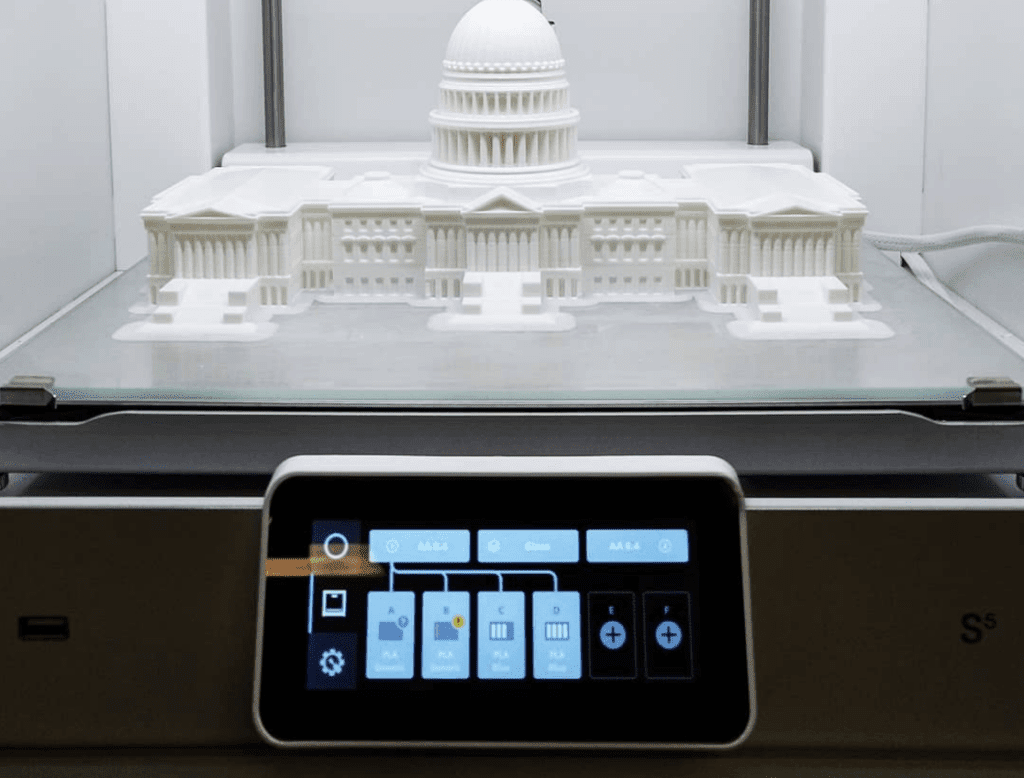

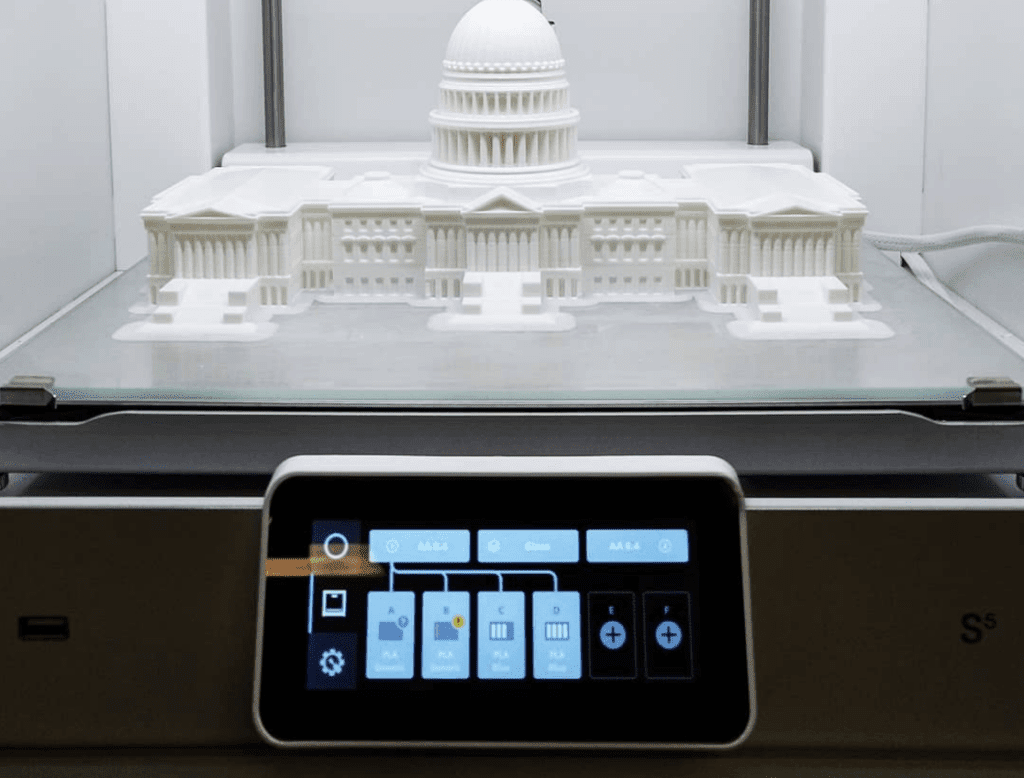

To produce the final physical model combination of 3D printing, laser etching and CNC milling was used. The digital model was separated into quadrants that could be produced individually and then assembled modularly.

The solution developed by 3D Herndon was first applied to model the center of Washington, DC. This location was chosen for the proof of concept because of the many high-profile events and unique security issues that are often in play in the city. Using a portion of the digital model a detailed physical model was produced comprising eight panels covering 128 square feet. Using this process for combining a range of technologies including lidar imagery, satellite maps and imagery, architectural modeling, mesh modeling and parametric modeling and production using 3D printing, laser etching and CNC milling.