Universities need small SLS 3D printers. Comparison with big SLS devices.

Education sector uses 3D printers a lot. From simple and cheap FDMs to the most sophisticated metal printing devices. Teaching, testing, printing a lot. Those devices need to be simple, affordable, high tech and easy to repair.

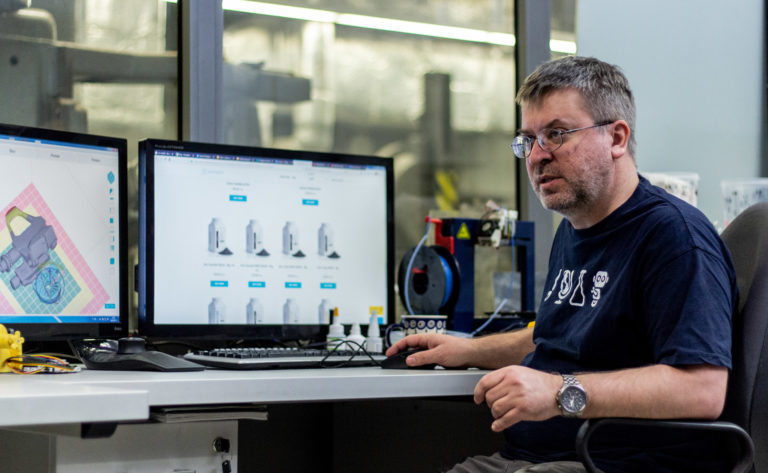

Piotr Dudek is adjunct professor at AGH University of Science and Technology. He runs an additive manufacturing lab equipped with many different 3D printers. From FDMs, via SLA, to powder and SLS devices. Department of Manufacturing Systems in the Faculty of Mechanical Engineering and Robotics has vast additive manufacturing needs. The main fields of his academic interests are rapid prototyping and reverse engineering. In his lab, 3D printers are used by both scientific researchers and students. The range of applications starts with student projects or master’s thesis and leads scientific research papers and material tests.

From different additive manufacturing technologies Dudek is especially interested in selective laser sintering (SLS) printers. There are several reasons.

First of all in SLS technology you can print almost any shape, without worrying about complicated geometry – says Piotr Dudek.

The freedom of creation is especially important. No matter if the internal or external structure of the element is complicated. His faculty already uses several powder based 3D printers from EOS, Zcorp and Sinterit.

The benefits of big machines are connected with their impressive print volume. If you need big parts printed at once it is hard to find other solutions. But there are also down sides as high price, difficult calibration and the need of special training for operators. It is also very expensive to print small parts, as you need to provide a lot of powder to start printing.

We are using the big EOS SLS 3D printer for a long time and we wanted to compare it with Sinterit Lisa, check the possibilities of it -says Piotr Dudek. In SLS technology every detail matters. The temperature of the printing chamber, powder distribution system, heating or laser moving mechanism are very precise and important features. We wanted to test if Sinterit’s device is the valuable solution. – adds Dudek.

One of the weak points of the big machines is that galvo laser steering system could be easily discalibrated during the transportation. Sinterit Lisa printer use gantry system so the printer could be pre-calibrated, which means that after taking it out of the box you don’t need to spend days on adjustments.

Another benefit is that you can use as little as one or two liters of the powder to start printing. It is a way cheaper solution, especially at universities, where you print a lot of different models for a large number of students and academics and it is not economical to print them separately on a big device.

Dealing with different materials

Advanced SLS users print from various groups of materials, with different melting point. It is important to carefully clean the printer while changing the material. In small devices it is an easy process, taking not longer than half an hour. In big machines sometimes you need to spend several hours and reaching all corners can be difficult.

Student friendly

3D printing is like riding a bike. You can’t do it comprehensively while someone is holding you behind your back. Just imagine letting students working on a device worth more than 250 000 USD on their own. I am not sure if it is even acceptable from the point of a warranty service. With desktop-sized device for less than 10 000 USD the risk is way lower. It is also simpler in use, so after a short, one hour training session, scholars can print without the external help. The more students can learn using professional technology the better their future projects will be. Not only at the university but mostly on the market they will join after graduation.

Source: Universities need small SLS 3D printers. Comparison with big SLS devices.